Understanding Minimum Order Quantity (MOQ)

This blog post emphasizes the importance of Minimum Order Quantity (MOQ) and how it can affect the pricing and inventory levels of products. Understanding MOQ is crucial when placing orders to avoid excess inventory or high purchase prices.

A fledgling business owner, A, is preparing for a sales business and is trying to start his real business by placing an order with a manufacturer. As he has not yet established a stable distribution channel, he plans to produce only a small amount of products and monitor the sales trend. However, the manufacturer demands a minimum order quantity (MOQ), which puts a brake on A's plan to produce a small amount.

If you are company selling products, you will encounter the term MOQ when negotiating contracts or placing orders with manufacturers. If you proceed with an order without knowing what MOQ is and following the demands of the manufacturer, you may end up with a huge inventory cost. Therefore, it is imperative that novice entrepreneurs, like A, acquire an understanding of the concept of MOQ and acknowledge the importance of considering MOQ requirements when procuring goods.

What is MOQ (Minimum Order Quantity)?

MOQ stands for "Minimum Order Quantity" which refers to the minimum number of products that can be ordered at one time. In other words, it is the smallest amount of product that a manufacturer is willing to produce in a single production run. For instance, if a manufacturer sets the MOQ at 100 units, this means that you need to order at least 100 items to place a purchase order. Since most manufacturers use MOQ as a basis for their pricing, it is essential to have a good understanding of the concept of MOQ when dealing with manufacturers.

Why is MOQ necessary?

MOQ can be seen as a form of declaration that manufacturers make to potential customers.

"In order to make a deal with us, you have to place an order for a certain quantity."

This is understandable because MOQ is directly related to the profitability of the manufacturer. To produce a single product in bulk, manufacturers have to design and implement a production process that involves investing a significant amount of capital. This process can include making a unique mold that is used for mass production, as well as incurring additional costs such as electricity, gas, raw material procurement, storage, and labor costs for running the equipment in the factory. Therefore, manufacturers establish the minimum order quantity that can be produced without incurring losses, taking into account these production costs.

MOQ can vary greatly depending on the manufacturer and the product being produced. Some manufacturers may require MOQs in the thousands, while others may offer MOQs that are even lower than a hundred units. Since each manufacturer has a different profit structure and production costs, it is nearly impossible to calculate the industry average MOQ. The only way to determine the MOQ for a specific manufacturer is to directly confirm it with them.

Why is it important to consider MOQ when placing an order?

If you're a seller like Mr. A, you might think that contracting with a manufacturer that has a low MOQ is the way to go, especially if you plan on producing in small quantities. However, it's not always that simple. While a low MOQ may seem attractive, it usually comes with a higher purchase price. And if your sales exceed expectations, you may need to purchase at an expensive price several times. On the other hand, dealing with a manufacturer with a high MOQ can result in a relatively lower purchase price. However, placing a high order quantity based only on a cheap purchase price can lead to excess inventory, which incurs significant management costs.

MOQ can be a crucial factor in the entire production process for companies that order multiple components to create a single finished product. For instance, a manufacturing company that creates one desk from five pieces of lumber needs to produce at least 200 desks every time to turn a profit. However, if the supplier of the raw materials requires an MOQ of 1,500 pieces of lumber, they will have no choice but to order 1,500 pieces of lumber, which is 500 pieces more than they need, leading to excess inventory storage.

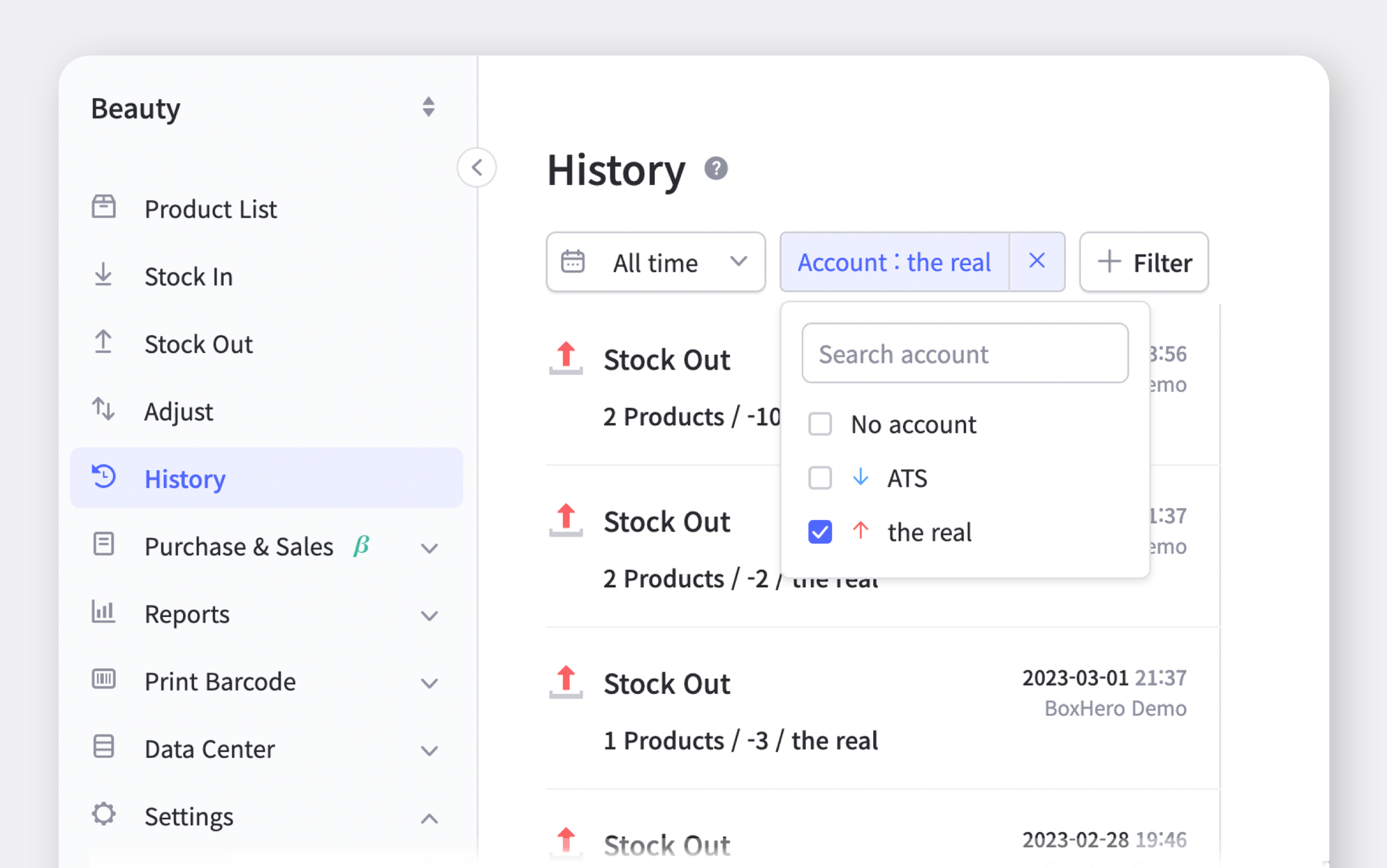

If your manufacturing company is facing recurring inventory issues, it's important to consider reviewing the appropriateness of your supplier's MOQ. With BoxHero's History feature, you can quickly assess incoming quantities by the supplier for a specific period, making it useful for reviewing order quantities. This feature allows you to track various inventory-related changes, such as incoming, outgoing, and adjustments. To review the order quantities for a particular supplier, simply click the +Filter button and select the company-the supplier indicated by the blue arrow. By clicking on each incoming item, you can see how much product was ordered at once in the detailed section on the right.

To get a more detailed comparison of order quantities, you can check the Sales Analysis section under the Purchase & Sales menu and compare the quantities by the supplier. Here, you can easily see the sales volume, revenue, order quantity, and purchase amount for a specific period. By selecting the View by Account checkbox at the top right, you can identify the products from which suppliers remain in the warehouse as inventory. With this information, you can negotiate reasonable prices and appropriate production quantities with the supplier and determine the MOQ that fits your business.